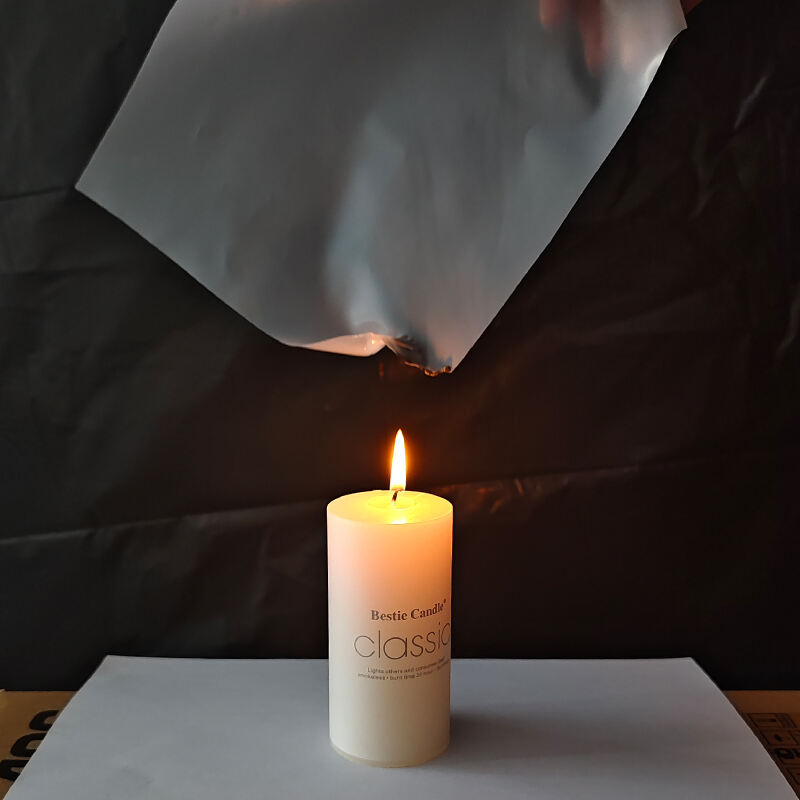

compostable plastic film

Compostable plastic film represents a groundbreaking advancement in sustainable packaging solutions. This innovative material combines the functionality of traditional plastic films with eco-friendly end-of-life disposal. Made from renewable resources such as corn starch, vegetable oils, and cellulose, these films are designed to completely break down into natural elements within industrial composting facilities. The technology behind compostable plastic films ensures they maintain the necessary barrier properties for product protection while meeting international standards for biodegradability. These films offer excellent printability, heat-sealing capabilities, and transparency, making them suitable for various packaging applications. They can be used in food packaging, agricultural mulch films, shopping bags, and other consumer goods packaging. The material's structure is engineered to provide adequate shelf life for packaged products while ensuring complete decomposition when disposed of properly. What sets these films apart is their ability to maintain strength and flexibility during use while breaking down into non-toxic components within 180 days under proper composting conditions.