custom silage bagging

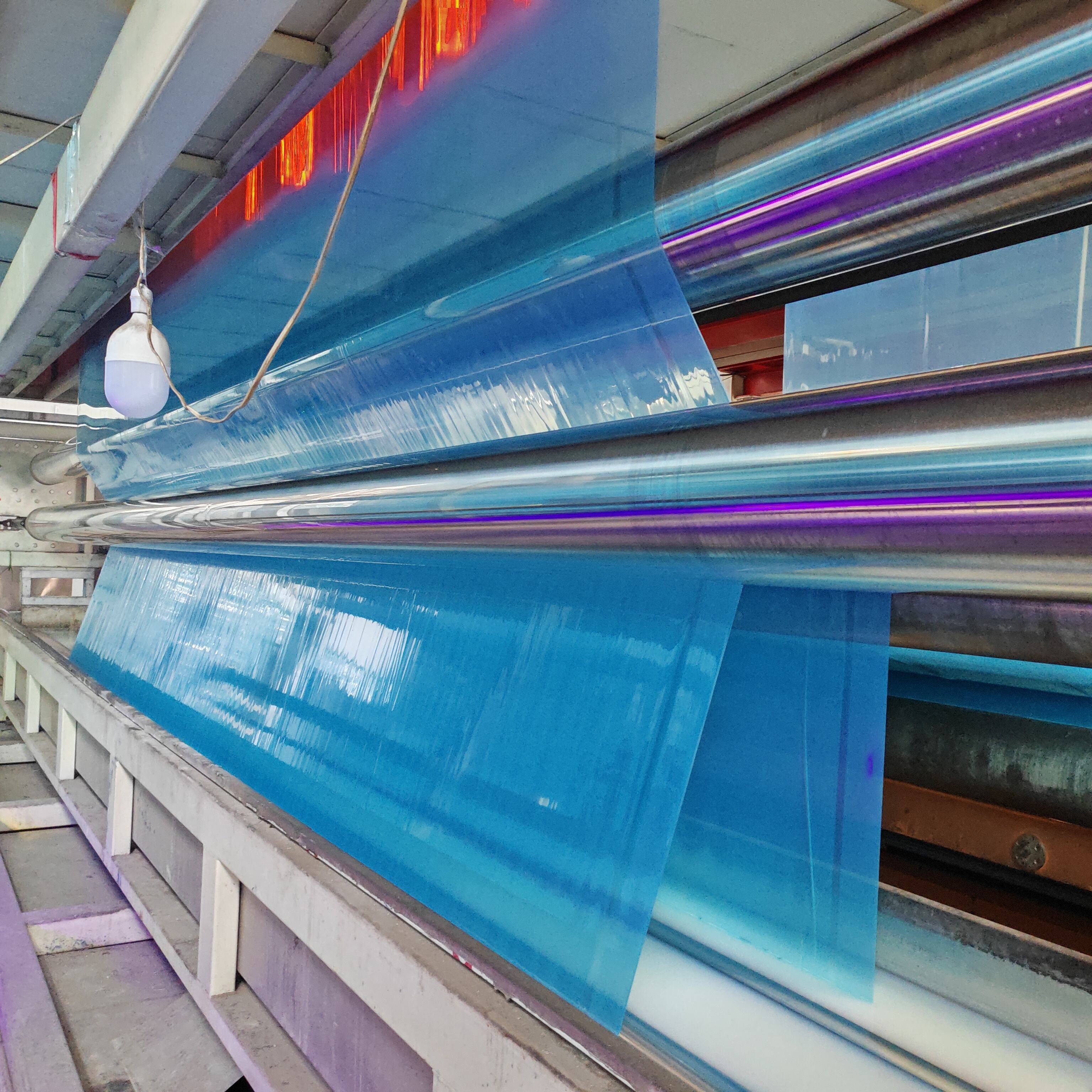

Custom silage bagging represents a revolutionary approach to modern agricultural storage and preservation. This advanced system allows farmers and agricultural businesses to efficiently store and preserve various types of forage materials while maintaining optimal nutritional value. The process involves compacting and storing silage in specially designed bags that create an anaerobic environment, essential for proper fermentation and preservation. These bags, typically ranging from 8 to 12 feet in diameter and up to 500 feet in length, are filled using specialized machinery that ensures consistent density and compression. The technology incorporates advanced monitoring systems that maintain precise pressure levels during the bagging process, preventing air pockets and ensuring uniform fermentation. The custom aspect allows for adaptability to different crop types, storage needs, and farm sizes, making it a versatile solution for various agricultural operations. The system includes features such as UV protection, multiple layer construction for enhanced durability, and built-in oxygen barriers that extend storage life. This method has proven particularly effective for storing corn silage, haylage, grain, and other high-moisture agricultural products, offering flexibility in harvest timing and storage location choices.