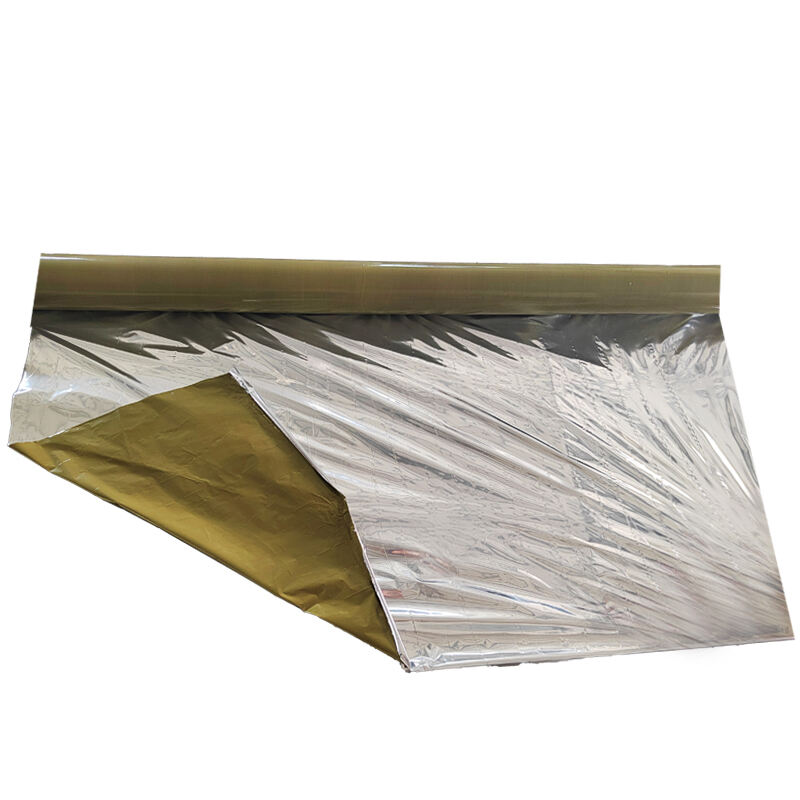

heat shrink film factory

A heat shrink film factory represents a state-of-the-art manufacturing facility dedicated to producing high-quality shrink films for various packaging applications. These facilities utilize advanced extrusion technology and precise temperature control systems to create films that offer superior shrinkage properties and excellent clarity. The manufacturing process involves carefully selected raw materials, primarily polyolefin resins, which undergo sophisticated multi-layer co-extrusion processes. Modern heat shrink film factories incorporate automated quality control systems that monitor thickness uniformity, shrink properties, and optical characteristics throughout production. The facility's production lines are equipped with cutting-edge winding systems that ensure consistent roll quality and dimensional stability. Environmental control systems maintain optimal temperature and humidity levels to ensure product consistency. The factory typically includes specialized testing laboratories for quality assurance, where films undergo rigorous testing for mechanical properties, shrink performance, and optical characteristics. Storage facilities are climate-controlled to maintain product integrity, while dedicated loading areas facilitate efficient distribution. These facilities often feature energy-efficient systems and waste recycling programs, demonstrating commitment to sustainable manufacturing practices. The factory's technical capabilities extend to producing custom film solutions with varying thickness, strength, and shrinkage characteristics to meet specific customer requirements.