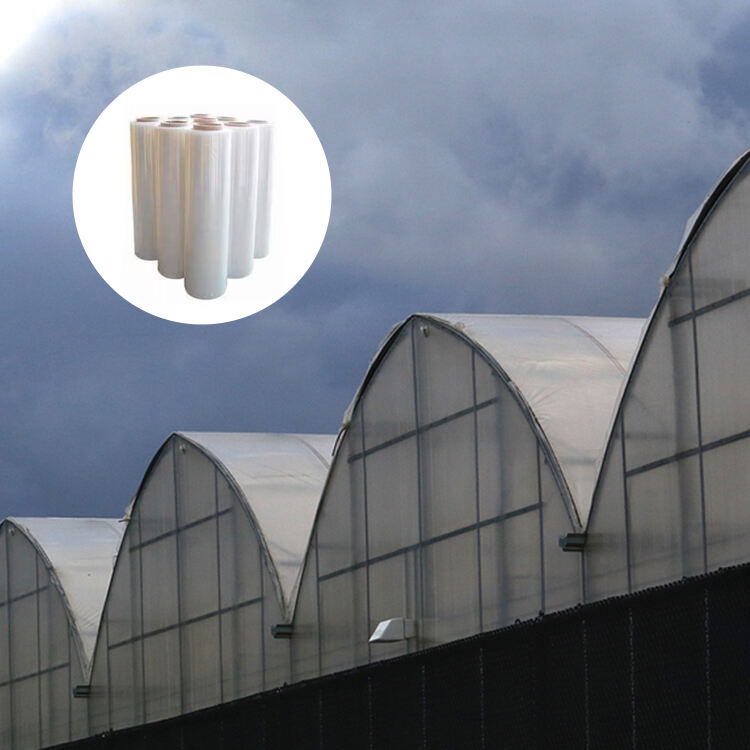

fatar film tsari

Kaiwarka filimu na kasa suna daidai da cikakken nan a matsayin fasalin da ke duniya ta wuce daidai da idonƙe filimun gabatarwa ake samfara da yanki filimin gabatarwa a kan kasa modern. Filimin fasalin nan suna daidai da takardun extrusion technology wannan da systemin kontrolin idonƙe ake samfara da sabon ayyukan filimin fasalin, shugaban greenhouse covers, mulch films, da silage wraps. Takardun produksi na kaiwarka suna daidai da takardun processin polymer advanced, ake samfara da filimun ake bayyana mai tsarin UV, mai hanyar mara, da transmissionin rayuwa daidai. Labaratoriyoyin assurance na idonƙe a kan kaiwarka suka yi testin rigoroos da ke tabbata da each product ya kamata standardin international da fasalin. Systemins produksin automated na kaiwarka suna daidai da ƙasa filimun, strength, da clarity wani haifuwar waste da maximizing efficiency. Systemins storage da handling raw material suka samfara da flowin material optimal da idonƙen product, wani cooling da ventilation systems sophisticated suka samfara da conditionsin produksi ideal. Kaiwarka suna da departmentin research da development dedicated a yi filimun solutions innovative, ake samfara da fasalin needs evolving da concerns environmental. Wannan kasa fasalin na kasa suna daidai da linkin crucial a kan chainin supply na fasalin modern, a support enhanced crop yields da farming practices sustainable worldwide.