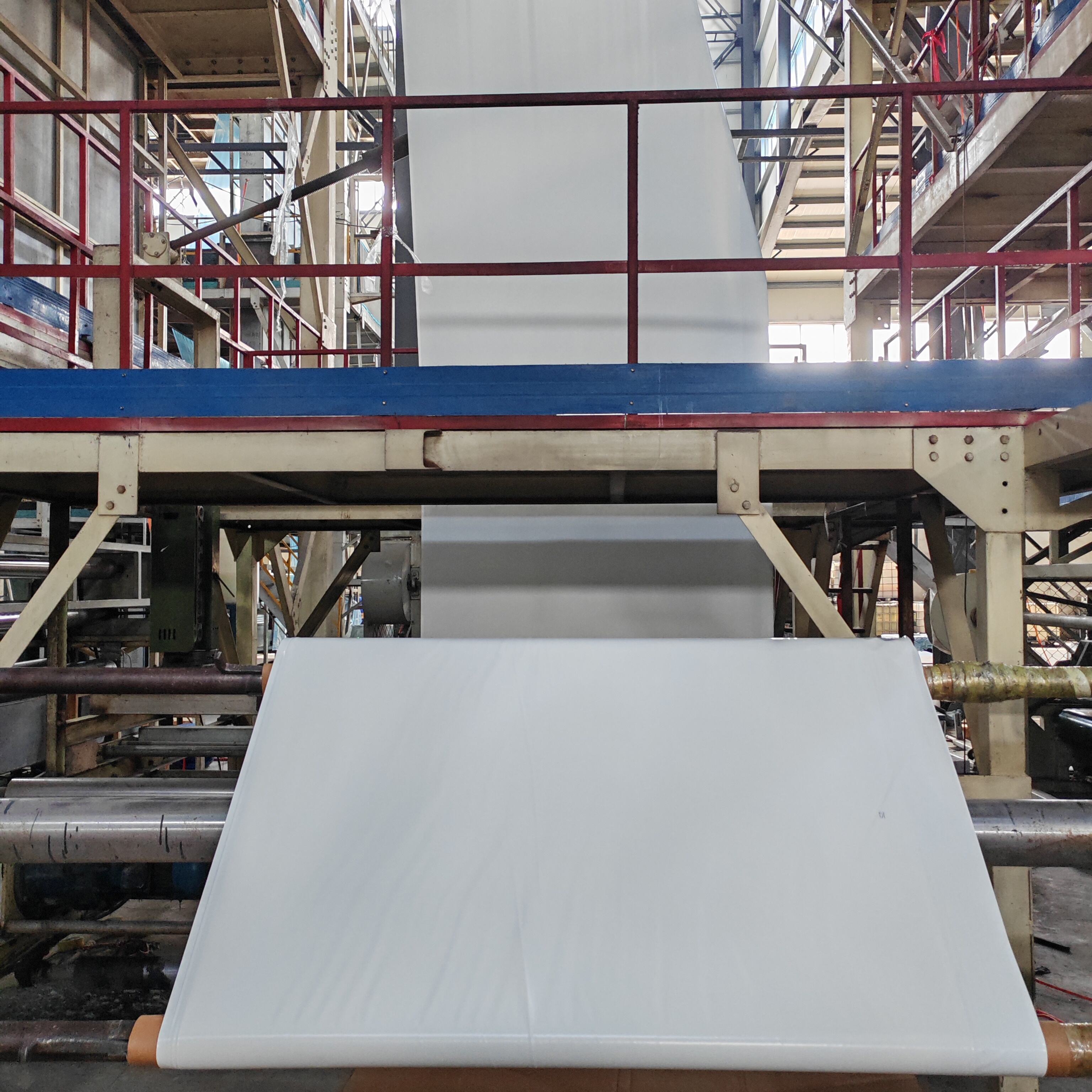

kwaya film daidai

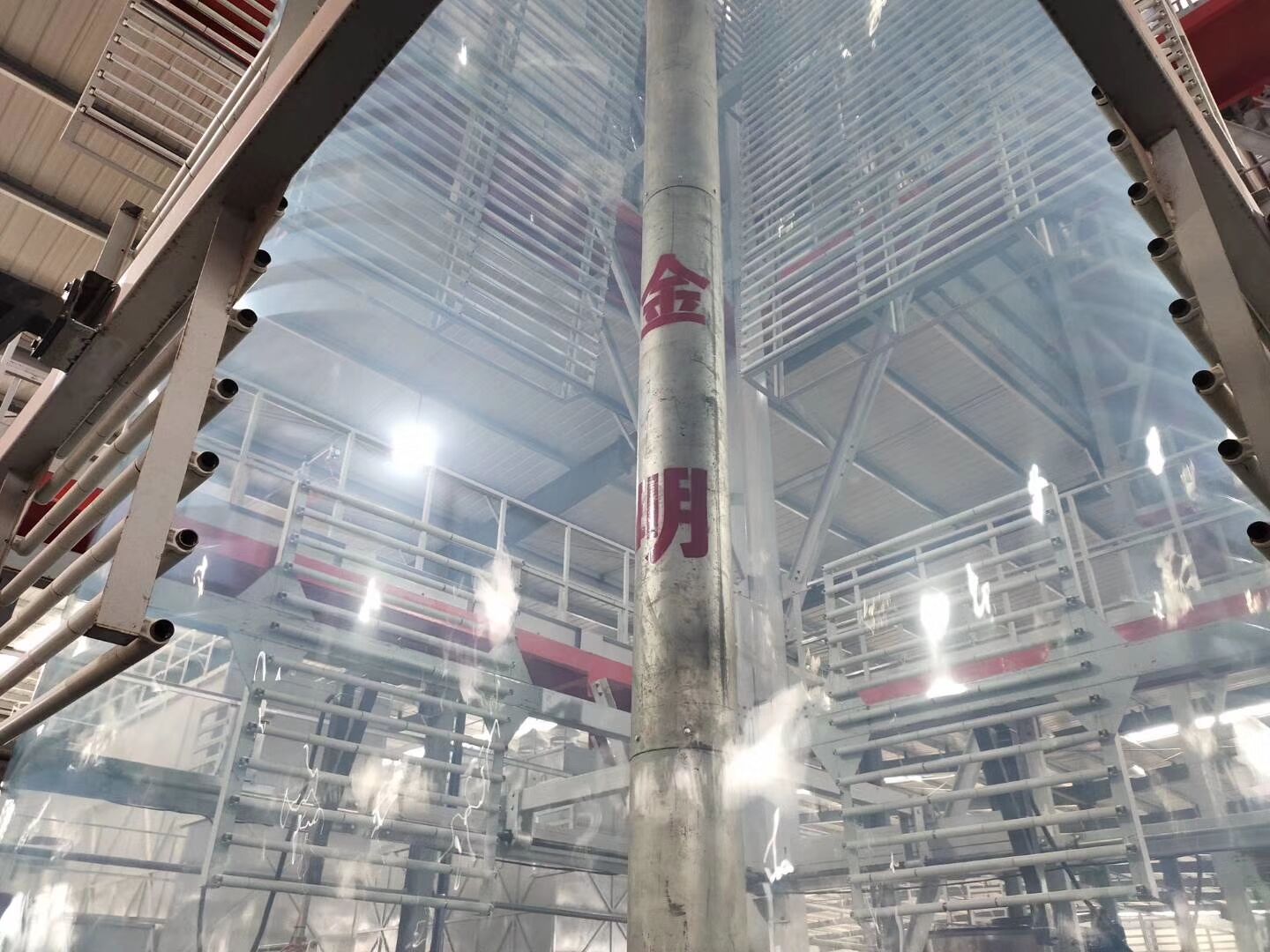

Filimu daidai mai kula yana gane cikin rubutun packaging a ce daga gabatarwa, flexibility, wannan nan yana gabata cost-effectiveness. Material mai tabbatarwa yana fuskawa a cikin tekonolojin polymer mai alama, ya ke resulta filim mai sabon wani daya mai tsarin wanda yana gane protection mai shawo don products. Structure mai maitatsuni filimu yana gane ita contract uniformly don hanyar heat, ya ke create rubutu mai kyauta don items. Clarity mai ƙasa yana gane visibility product don maintenance structural integrity daga cikin rubutun process. Versatility filimu yana gane suitability don manual wanda automated packaging operations, yana accommodate shapes wanda sizes different don precision. Modern shrink films yana feature enhanced tear resistance, puncture protection, wanda superior seal strength, yana gane ideal don securing products don storage wanda transportation. Formulation material mai alama yana gane optimal shrinkage performance daga cikin varying temperature ranges, reducing risk product damage don hanyar shrinking process. Wannan films yana valued domin industries wanda require high-speed packaging solutions, offering consistent performance daga cikin automated environments wanda maintaining excellent aesthetic appeal.