proizvođač poljoprivrednog filma

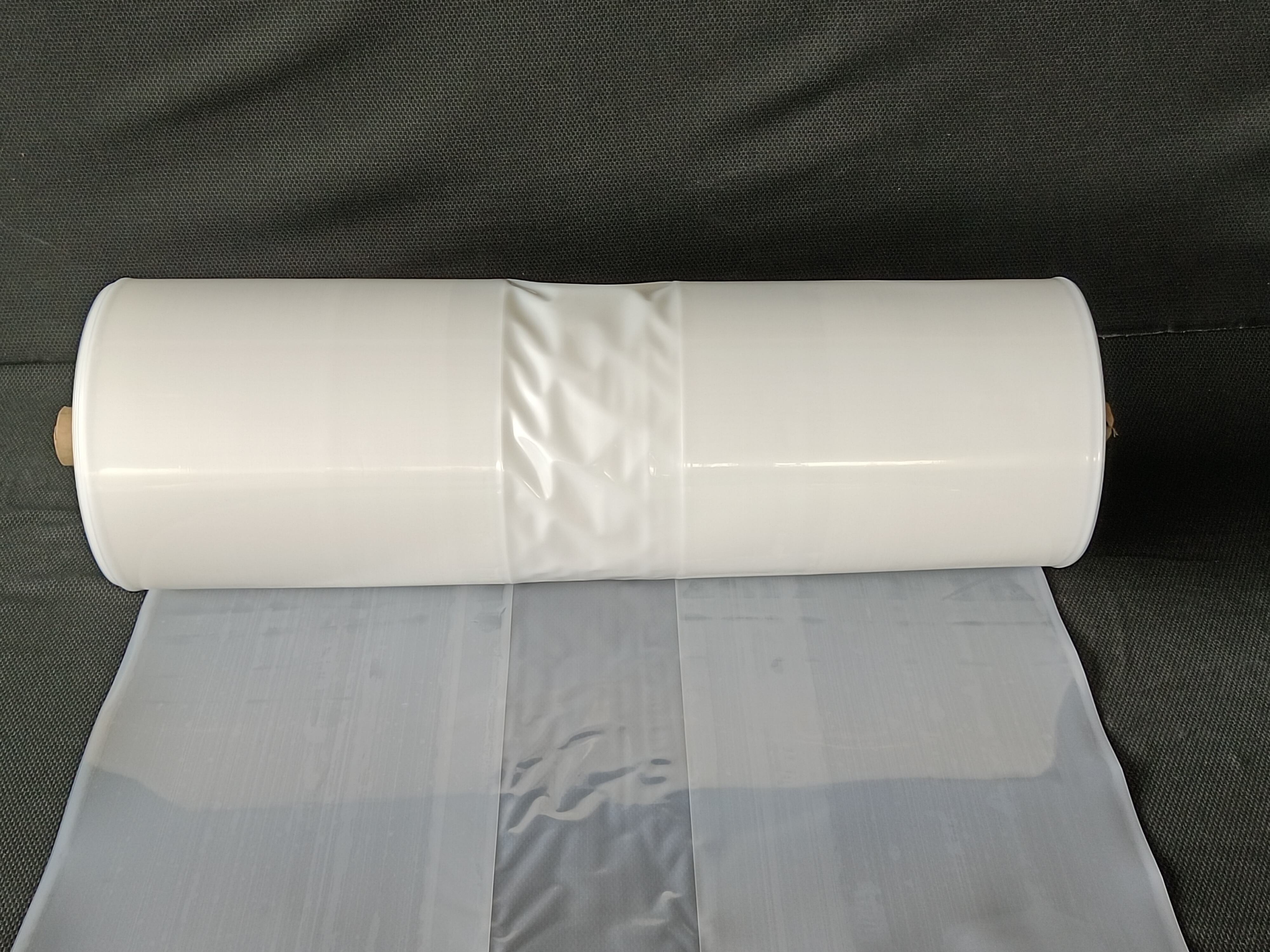

Proizvođač poljoprivrednog filma predstavlja temeljni kamen u savremenoj tehnologiji poljoprivrede, specializirajući se na proizvodnju visokokvalitetnih zaštitnih filmova koji revolucioniraju rasluživanje biljaka i njihovo upravljanje. Ti proizvođači koriste najnovije tehnologije ekstruzije i napredne znanosti o materijalima kako bi stvorili trajne, vremenski otporne filme koji služe više poljoprivrednih svrha. Proces proizvodnje uključuje sofisticirane sustave kontroliranja kvalitete, osiguravajući konstantnu performancu proizvoda u različitim poljoprivrednim primjenama. Ove postrojbe obično imaju najnovije proizvodne linije sposobne proizvesti više vrsta filmova, uključujući pokrivnice za šatorice, mulčne filme i omot za silo. Proces proizvodnje uključuje UV stabilizatore, termoregulatora i protuambrušne svojstva, rezultirajući filmovima koji učinkovito zaštićuju biljke dok optimiziraju uvjete za rast. Savremeni proizvođači poljoprivrednih filmova također prioritetno stavljaju održivost, implementirajući prijateljske okolišu metode proizvodnje i razvijajući biodegradabilne opcije kako bi ispunili rastuće okolišne brige. Njihove mogućnosti proizvodnje proširuju se na prilagođene rješenja, dopuštajući poljoprivrednicima da zahtijevaju specifična svojstva filmova na temelju njihovih jedinstvenih poljoprivrednih potreba, klimatskih uvjeta i vrsta biljaka.