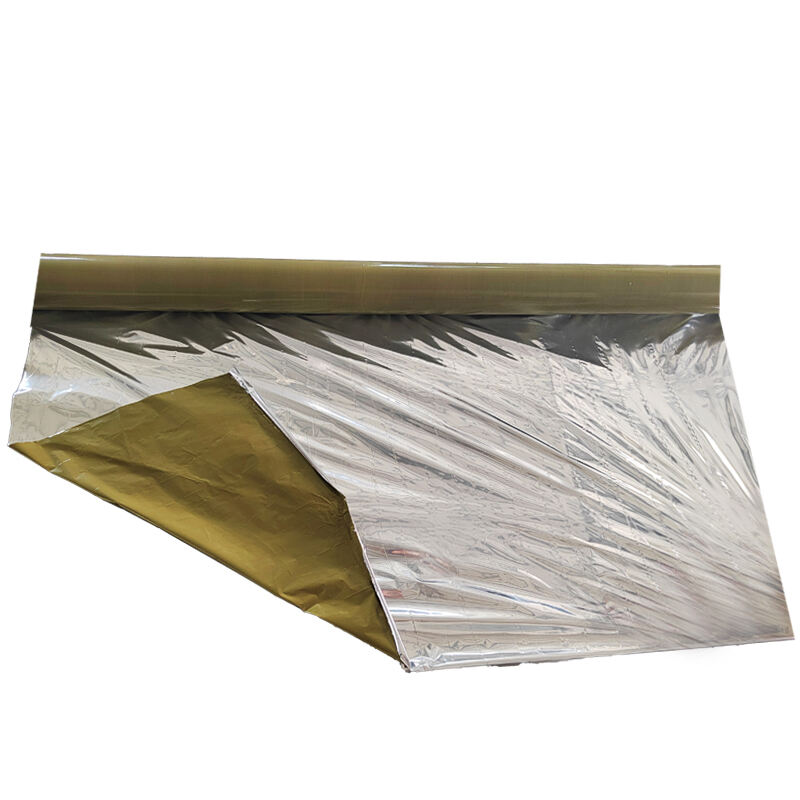

bioplastic film

Bioplastic film represents a revolutionary advancement in sustainable packaging solutions, offering an environmentally conscious alternative to traditional petroleum-based plastics. This innovative material is derived from renewable resources such as corn starch, vegetable oils, and other plant-based materials, making it both biodegradable and compostable. The film exhibits remarkable versatility in its physical properties, including adjustable thickness, transparency, and barrier capabilities against moisture and gases. Its manufacturing process involves state-of-the-art extrusion technology that ensures consistent quality and customizable characteristics to meet diverse packaging requirements. The film's molecular structure can be engineered to provide specific shelf-life properties, making it ideal for food packaging, agricultural applications, and consumer goods packaging. Its ability to maintain structural integrity while being environmentally friendly has made it increasingly popular in industries seeking sustainable alternatives. The material demonstrates excellent printability and heat-sealing properties, ensuring compatibility with existing packaging equipment and processes. Additionally, bioplastic film can be modified to incorporate antimicrobial properties or UV protection, extending its utility across various applications from fresh produce packaging to industrial wrapping solutions.