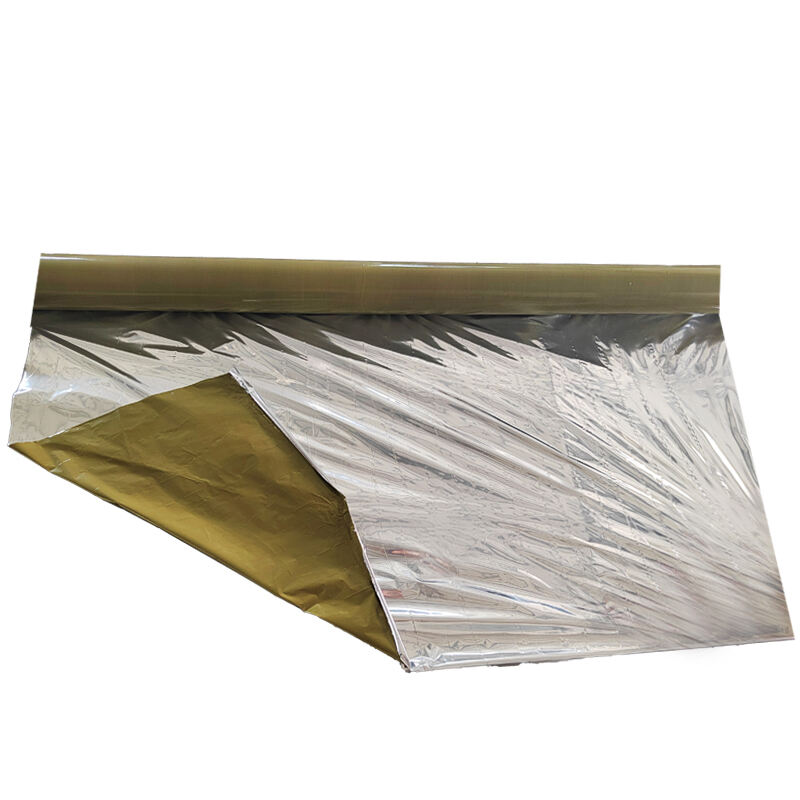

flexible packaging films

Flexible packaging films represent a revolutionary advancement in modern packaging technology, offering versatile solutions for various industries. These films are engineered to provide superior protection while maintaining product integrity through multiple layers of specialized materials. The primary function of flexible packaging films is to create a protective barrier that shields products from external factors such as moisture, oxygen, light, and contamination. These films are manufactured using advanced polymer technology, incorporating multiple layers that can be customized based on specific requirements. The films feature various properties including heat resistance, puncture resistance, and excellent sealability, making them suitable for diverse applications. They are extensively used in food packaging, pharmaceutical products, personal care items, and industrial goods. The technology behind flexible packaging films allows for enhanced shelf life of products while maintaining their freshness and quality. Their adaptability enables them to conform to different shapes and sizes, maximizing storage efficiency and reducing transportation costs. Modern flexible packaging films also incorporate smart features such as easy-open systems, resealable options, and modified atmosphere packaging capabilities.