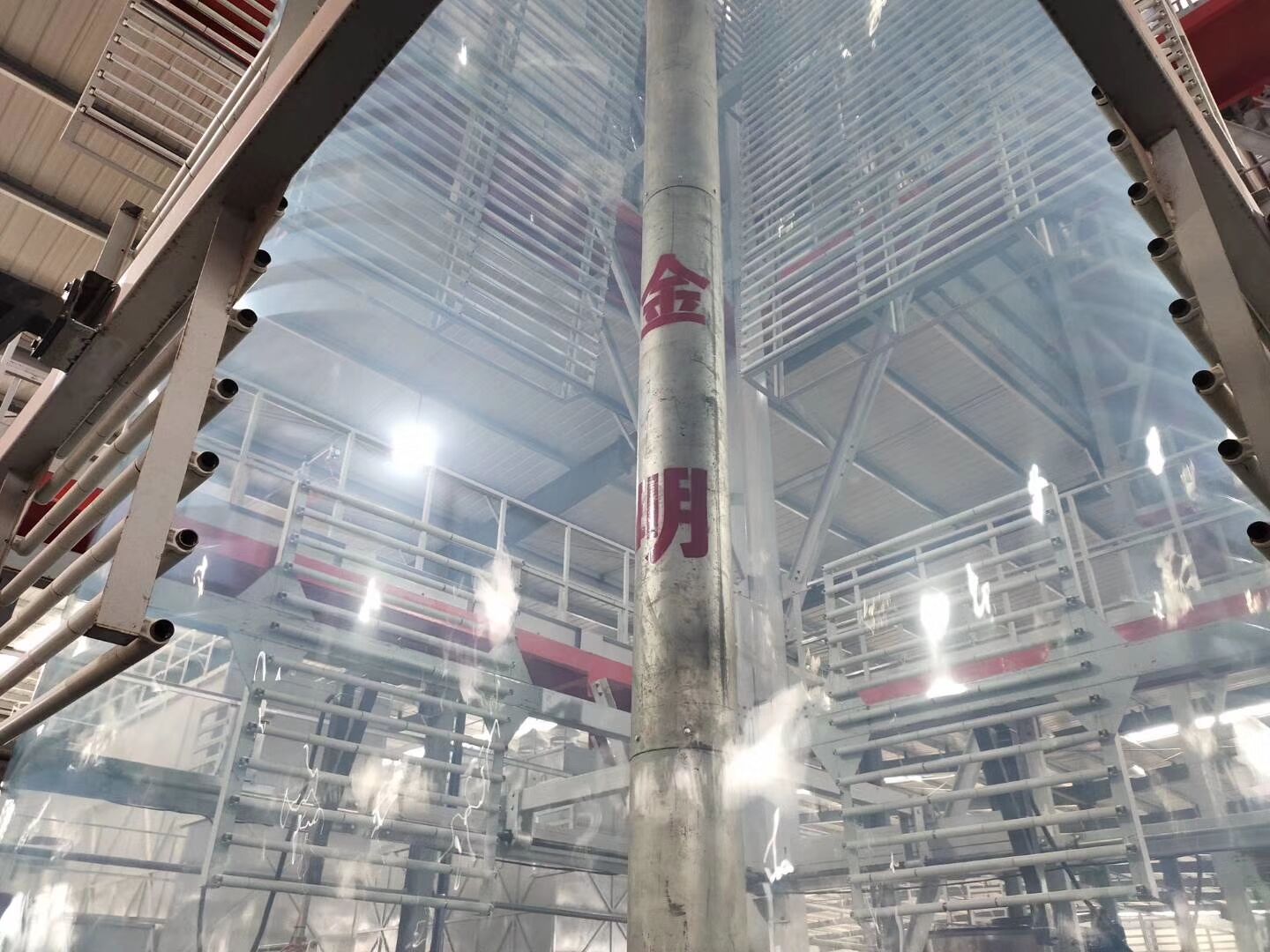

packaging film factory

A packaging film factory represents a state of the art manufacturing facility dedicated to producing high quality flexible packaging solutions for various industries. These facilities utilize advanced extrusion technology and precision engineering to create films that meet diverse packaging requirements. The factory incorporates multiple production lines equipped with sophisticated machinery for blown film extrusion, cast film production, and multilayer film manufacturing. Quality control systems monitor every stage of production, ensuring consistent material properties and dimensional accuracy. The facility typically features automated material handling systems, temperature controlled environments, and clean room conditions for specialized film production. Modern packaging film factories employ innovative technologies for surface treatment, including corona treatment and plasma systems, enhancing the films printability and adhesion properties. The production capabilities extend to various film types, including polyethylene, polypropylene, and specialty barrier films, with thickness ranges from ultra thin to heavy gauge materials. These facilities also maintain research and development departments focused on creating custom solutions and improving existing products through material science and process optimization. Environmental control systems and waste reduction protocols ensure sustainable manufacturing practices while maintaining high production efficiency.