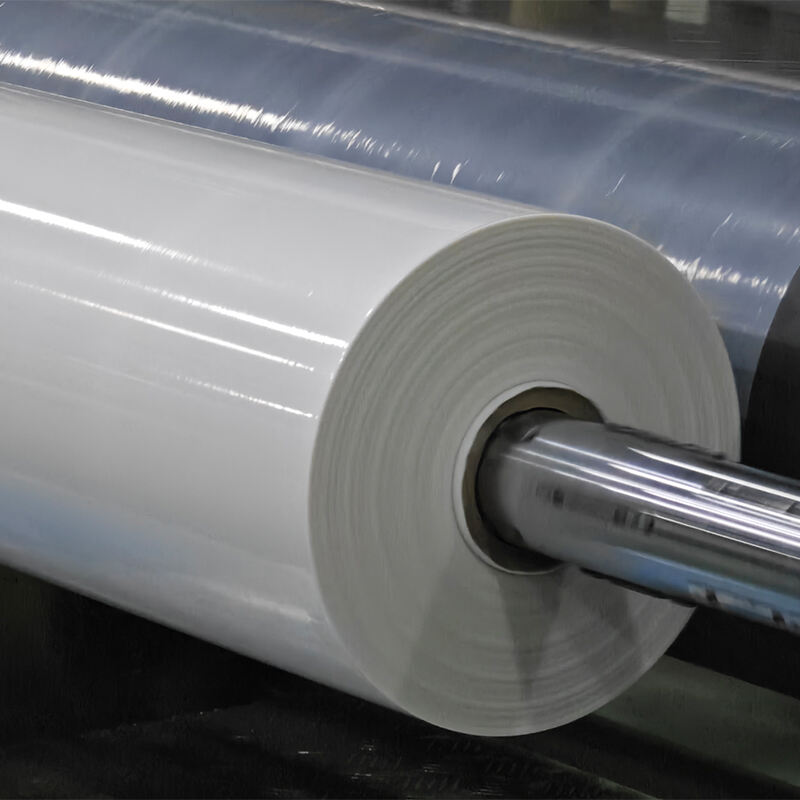

heat shrink plastic wrap

Heat shrink plastic wrap is a versatile packaging solution that revolutionizes product protection and presentation. This specialized material consists of polymer plastic films engineered to contract when exposed to controlled heat, creating a tight, protective seal around items. The wrap's molecular structure allows it to shrink uniformly, reducing its size by up to 40% while maintaining structural integrity. When heat is applied through specialized heat tunnels or heat guns, the material conforms precisely to the object's shape, creating a professional, tamper-evident barrier. The technology behind heat shrink wrap involves cross-linked polymer chains that respond to thermal energy by realigning and contracting. This process results in a durable, crystal-clear finish that enhances product visibility while providing superior protection against dust, moisture, and tampering. Common applications include packaging electronics, food products, beverages, consumer goods, and bundling multiple items together. The material's versatility makes it suitable for objects of various sizes and shapes, from small electronic components to large industrial equipment. Modern heat shrink films also incorporate UV protection and anti-static properties, extending product shelf life and ensuring safe handling during transportation and storage.