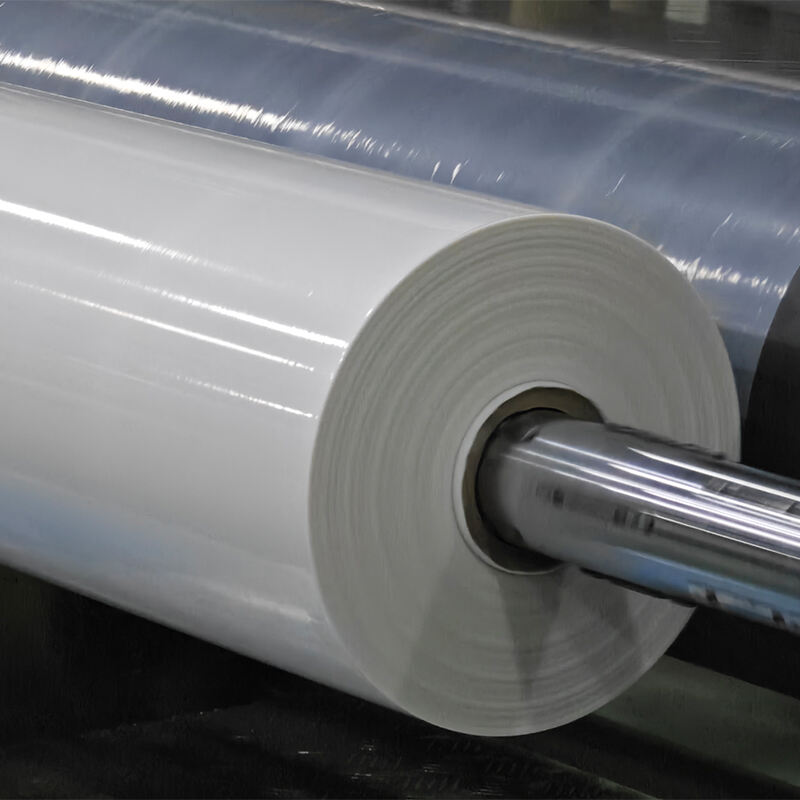

pe protective film

PE protective film represents a versatile solution in surface protection technology, engineered to safeguard various materials during manufacturing, transportation, and installation processes. This specialized film consists of a low-density polyethylene base with a carefully formulated adhesive layer that provides temporary protection without leaving residue upon removal. The film's thickness typically ranges from 30 to 100 microns, offering varying degrees of protection based on specific application requirements. It effectively shields surfaces from scratches, dust, moisture, and minor impacts while maintaining perfect visibility of the protected surface. The film's UV stability ensures it remains intact and easily removable for up to 12 months in various environmental conditions. Its advanced adhesive technology allows for clean removal without leaving marks or affecting the protected surface's integrity. PE protective film finds extensive applications across multiple industries, including electronics manufacturing, automotive production, construction materials, and household appliances. The film's ability to conform to complex shapes and surfaces makes it particularly valuable in protecting irregular or curved surfaces while maintaining consistent adhesion throughout its service life.