pe film manufacturer

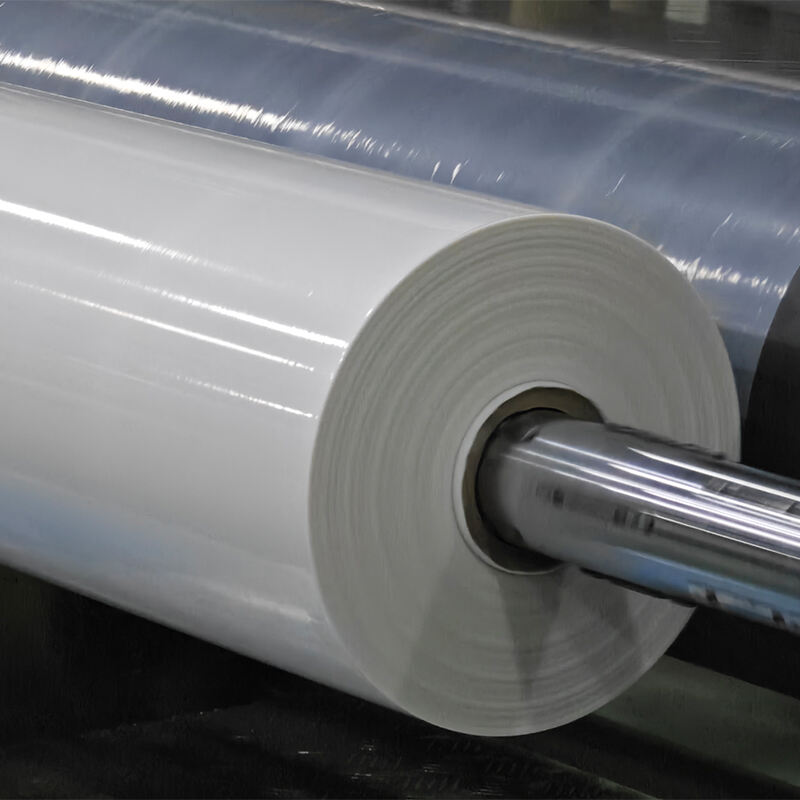

A PE film manufacturer specializes in producing high-quality polyethylene films through advanced extrusion processes. These facilities utilize state-of-the-art machinery and precise control systems to create films with consistent thickness, strength, and clarity. The manufacturing process involves melting polyethylene pellets and extruding them into thin sheets using specialized dies and cooling systems. Modern PE film manufacturers employ computerized quality control systems that monitor parameters such as thickness, tensile strength, and optical properties throughout production. The facilities typically feature multiple production lines capable of producing various film types, from basic packaging films to specialized agricultural and construction films. These manufacturers often incorporate recycling systems to minimize waste and ensure environmental sustainability. Their capabilities extend to customizing film properties such as UV resistance, anti-static properties, and moisture barriers according to specific customer requirements. The production environment maintains strict cleanliness standards and temperature control to ensure product quality. Many manufacturers also integrate testing laboratories to verify film specifications and develop new formulations.