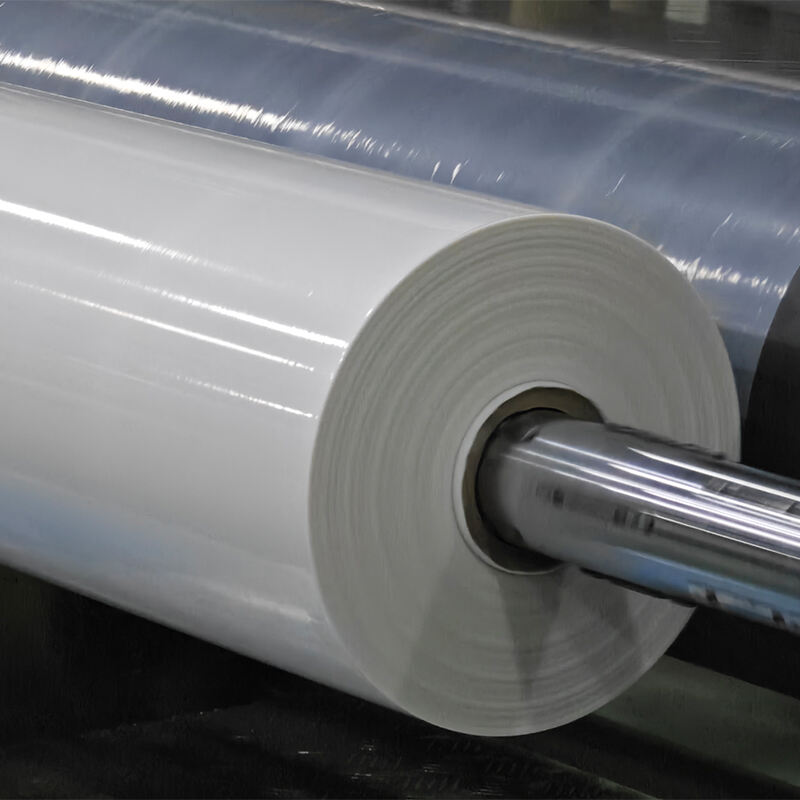

pe film packaging

PE film packaging represents a versatile and essential solution in modern packaging applications, combining durability with cost-effectiveness. This innovative packaging material, made from polyethylene, offers exceptional moisture resistance and protective qualities that make it ideal for various industrial and commercial uses. The film's molecular structure provides outstanding barrier properties, effectively protecting contents from external elements while maintaining product integrity. PE film packaging comes in various thicknesses and configurations, allowing for customization based on specific application requirements. From shrink wrap to stretch film, PE packaging demonstrates remarkable versatility in its application methods. The material's inherent flexibility enables it to conform to irregular shapes while maintaining structural integrity. Advanced manufacturing processes ensure consistent quality and reliable performance across different environmental conditions. The film's transparency can be adjusted to meet specific visibility requirements, while its surface can be treated for enhanced printability, making it excellent for branding and product information display. Additionally, PE film packaging offers significant advantages in terms of weight reduction compared to traditional packaging materials, contributing to reduced transportation costs and environmental impact.