heat shrink wrap film

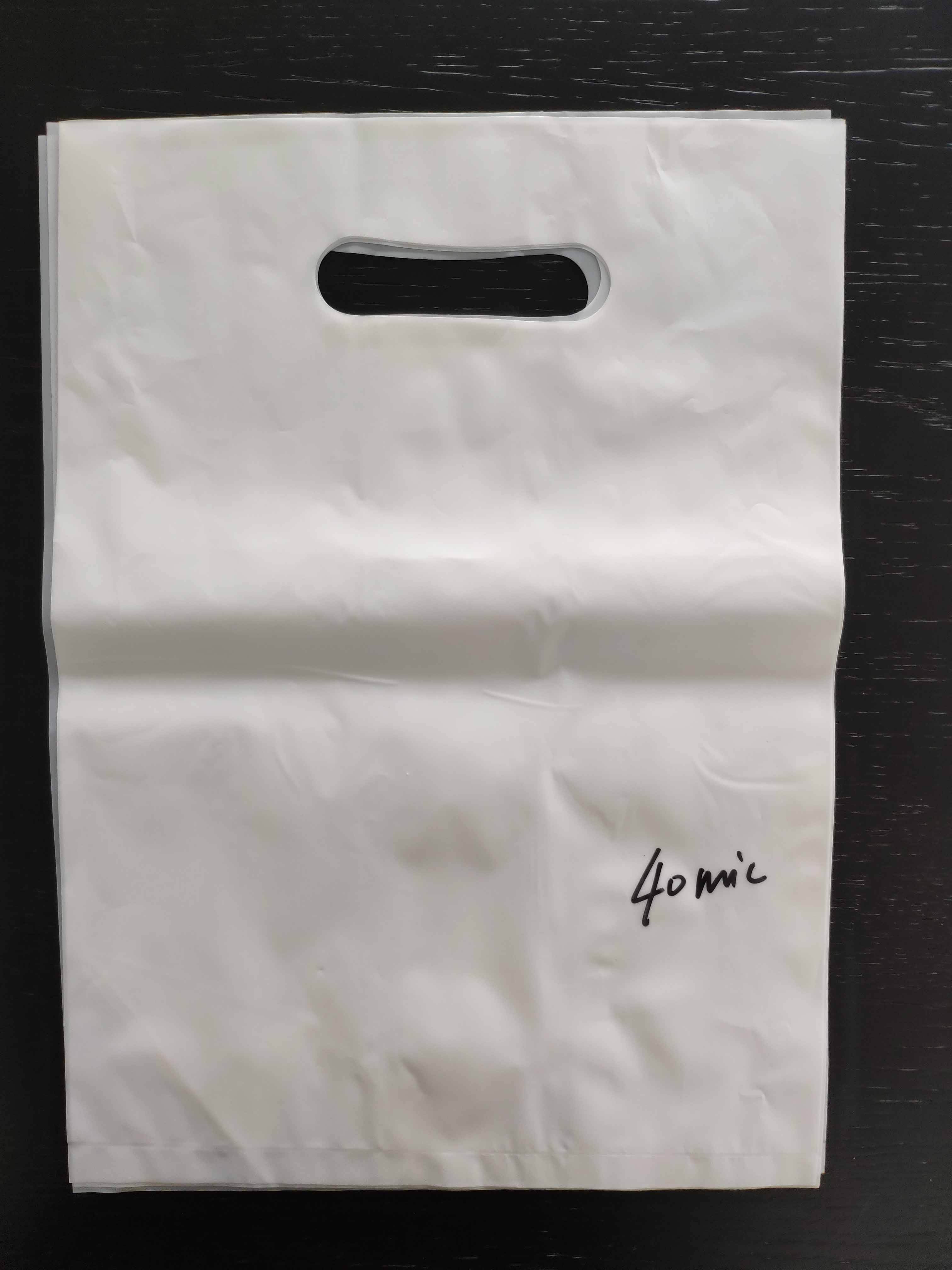

Heat shrink wrap film is a versatile packaging solution that revolutionizes product protection and presentation. This innovative material consists of polymer plastic film that contracts when exposed to heat, creating a tight, professional seal around items. The film's molecular structure is engineered to respond to specific temperature ranges, typically between 160-375°F (71-190°C), allowing for precise control during the shrinking process. The film's thickness can vary from 40-125 microns, making it suitable for diverse applications. When heated, the film shrinks up to 40% in length and 50% in width, conforming perfectly to the product's shape. This advanced packaging material incorporates UV protection, puncture resistance, and clarity enhancement technologies, ensuring products remain protected while maintaining visibility. Industries ranging from food and beverage to consumer electronics utilize heat shrink wrap film for individual items, multi-packs, and palletized loads. The film's versatility extends to both manual applications for small-scale operations and automated systems for high-volume production lines. Modern heat shrink films also feature innovations in sustainable materials, with some variants incorporating biodegradable components or reduced material usage while maintaining structural integrity.