po film manufacturer

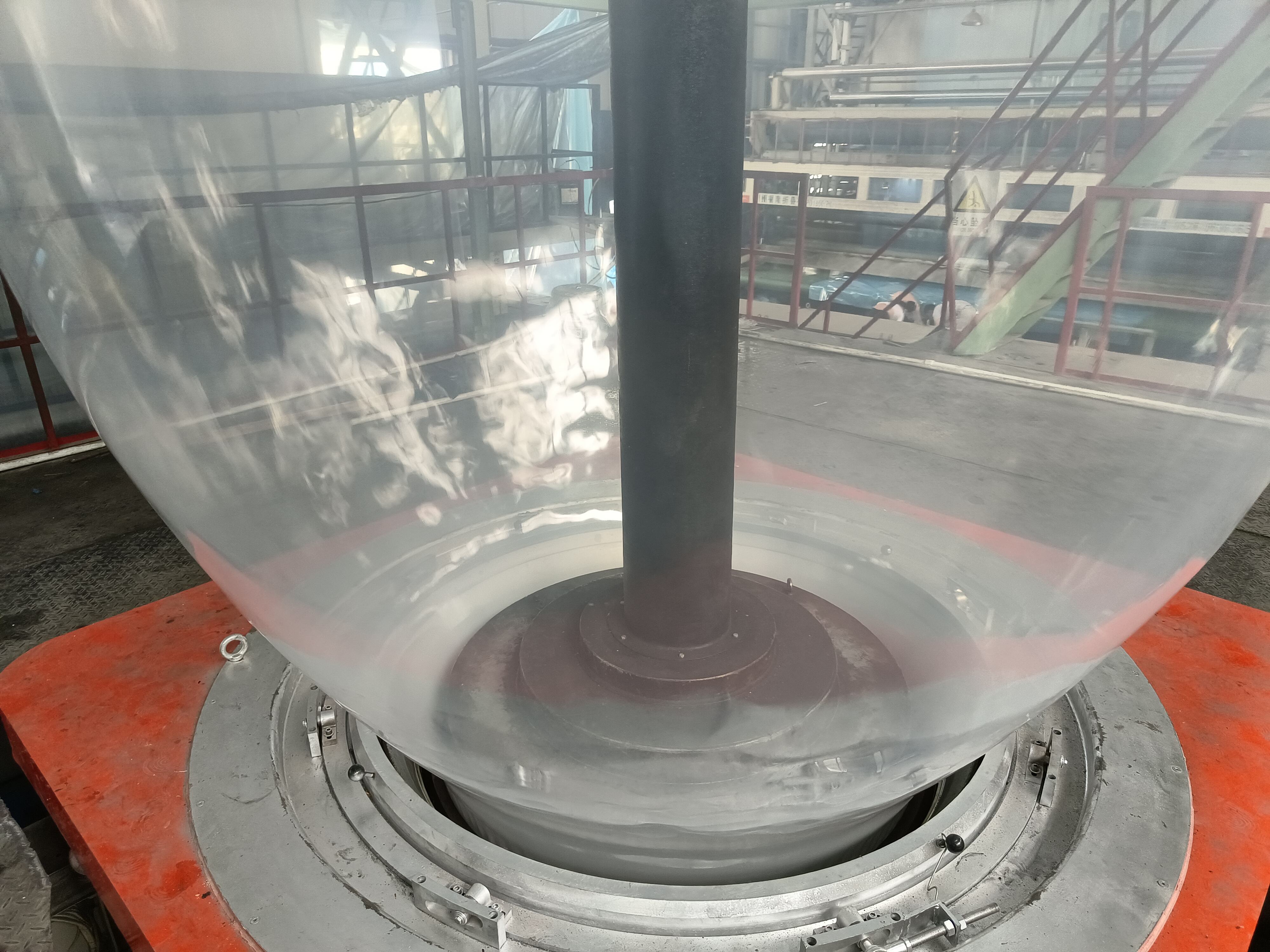

A PO film manufacturer specializes in producing high-quality polyolefin films through advanced manufacturing processes. These facilities utilize state-of-the-art extrusion technology and quality control systems to create versatile films that serve various industries. The manufacturing process involves careful selection of raw materials, precise temperature control, and sophisticated stretching techniques to achieve optimal film properties. Modern PO film manufacturers employ automated production lines equipped with advanced monitoring systems to ensure consistent product quality. These facilities often integrate sustainable practices, including energy-efficient equipment and waste reduction protocols. The manufacturing capabilities typically include both blown film and cast film technologies, allowing for the production of films with varying thicknesses, widths, and mechanical properties. Quality assurance laboratories within these facilities conduct rigorous testing for physical properties, optical characteristics, and surface treatment levels. Many manufacturers also offer customization options, including specific film formulations, surface treatments, and multi-layer structures to meet diverse customer requirements. The production environment is maintained under strict cleanliness standards to prevent contamination and ensure product integrity.