Flexible Production Capabilities

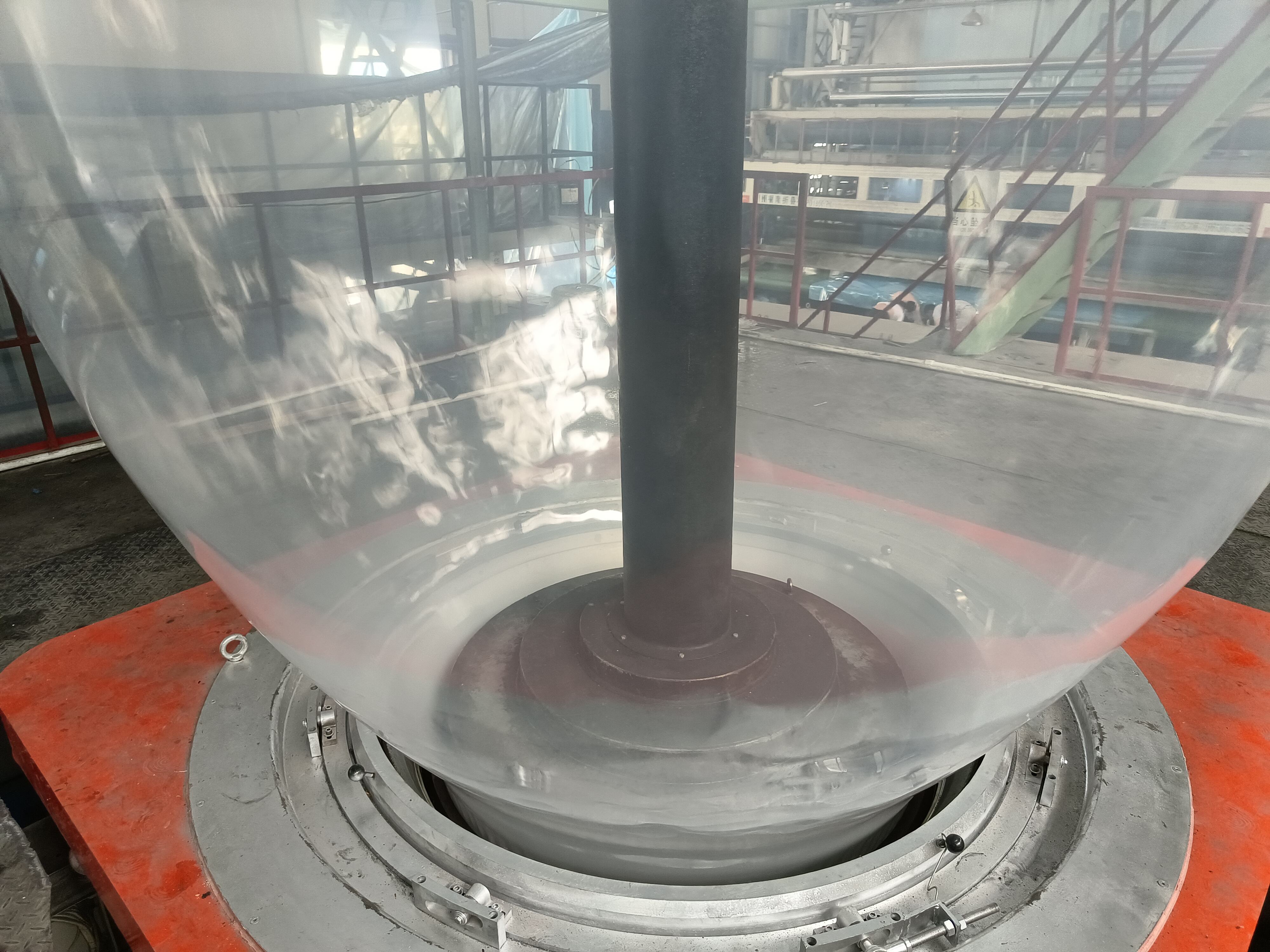

The factory's flexible production system stands as a testament to modern manufacturing adaptability. Multiple production lines can be rapidly reconfigured to accommodate different film specifications, ranging from ultra-thin packaging films to specialized industrial applications. Advanced die technology allows for precise control over film properties, including thickness profiles, surface characteristics, and mechanical properties. The system's quick-change capabilities minimize downtime during product transitions, maximizing operational efficiency. This flexibility extends to customization options, enabling the production of films with specific additives, colors, or surface treatments according to customer requirements. The factory's ability to handle various raw materials and produce multi-layer films provides extensive possibilities for product development and application-specific solutions.