po film vendors

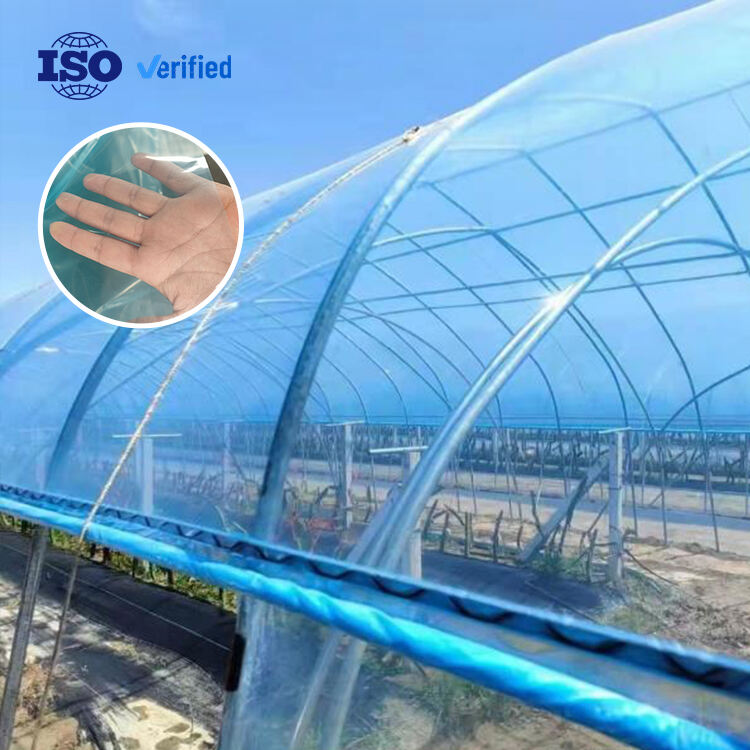

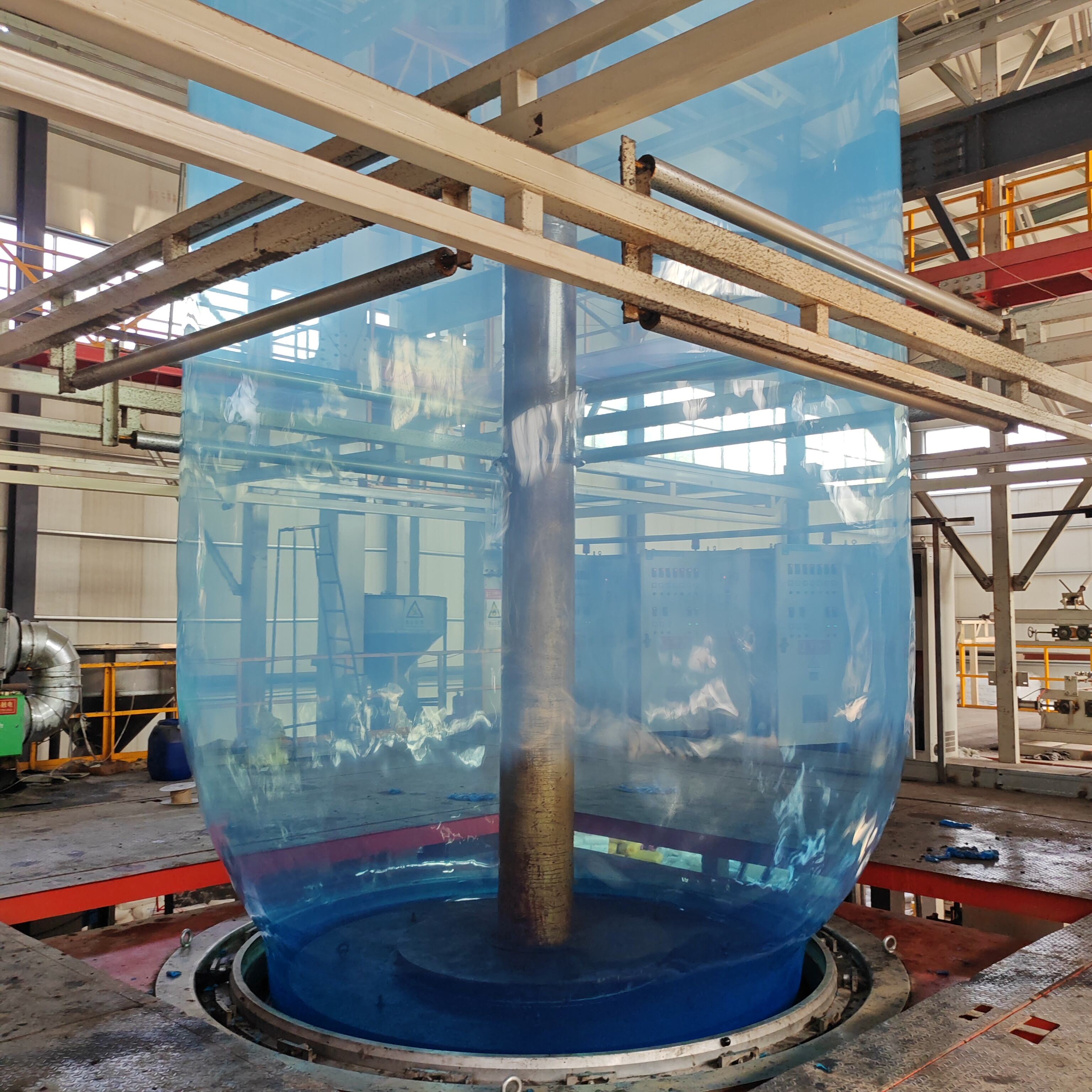

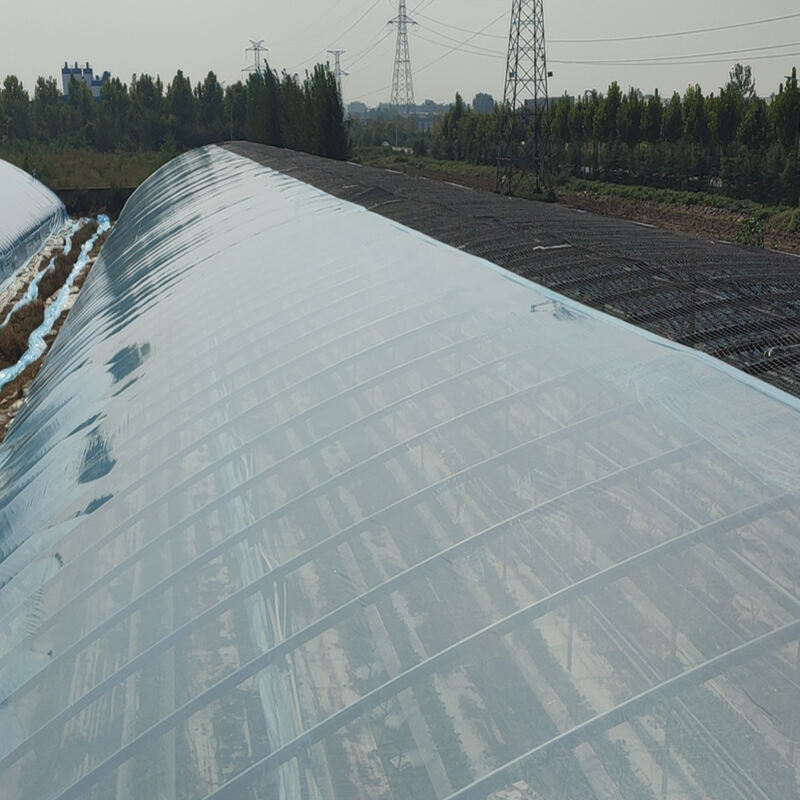

PO film vendors play a crucial role in the packaging and industrial materials sector, specializing in the production and distribution of polyolefin shrink films. These vendors provide high-quality oriented films that offer exceptional clarity, strength, and versatility for various applications. The films are manufactured through a sophisticated stretching process that aligns polymer molecules, resulting in enhanced mechanical properties and optical characteristics. Modern PO film vendors utilize advanced production technologies to create films with controlled shrinkage properties, excellent sealing capabilities, and superior moisture resistance. Their products are extensively used in beverage packaging, bundling applications, and industrial wrapping solutions. These vendors typically offer a comprehensive range of film thicknesses, from ultra-thin gauges for lightweight applications to heavier variants for industrial use. They maintain strict quality control measures throughout the production process, ensuring consistent film properties and performance. Many vendors also provide customization options, allowing clients to specify particular requirements for shrink ratios, clarity levels, and surface treatments. The films supplied by these vendors comply with various international safety and environmental standards, making them suitable for food contact applications and sustainable packaging solutions.