high quality po film

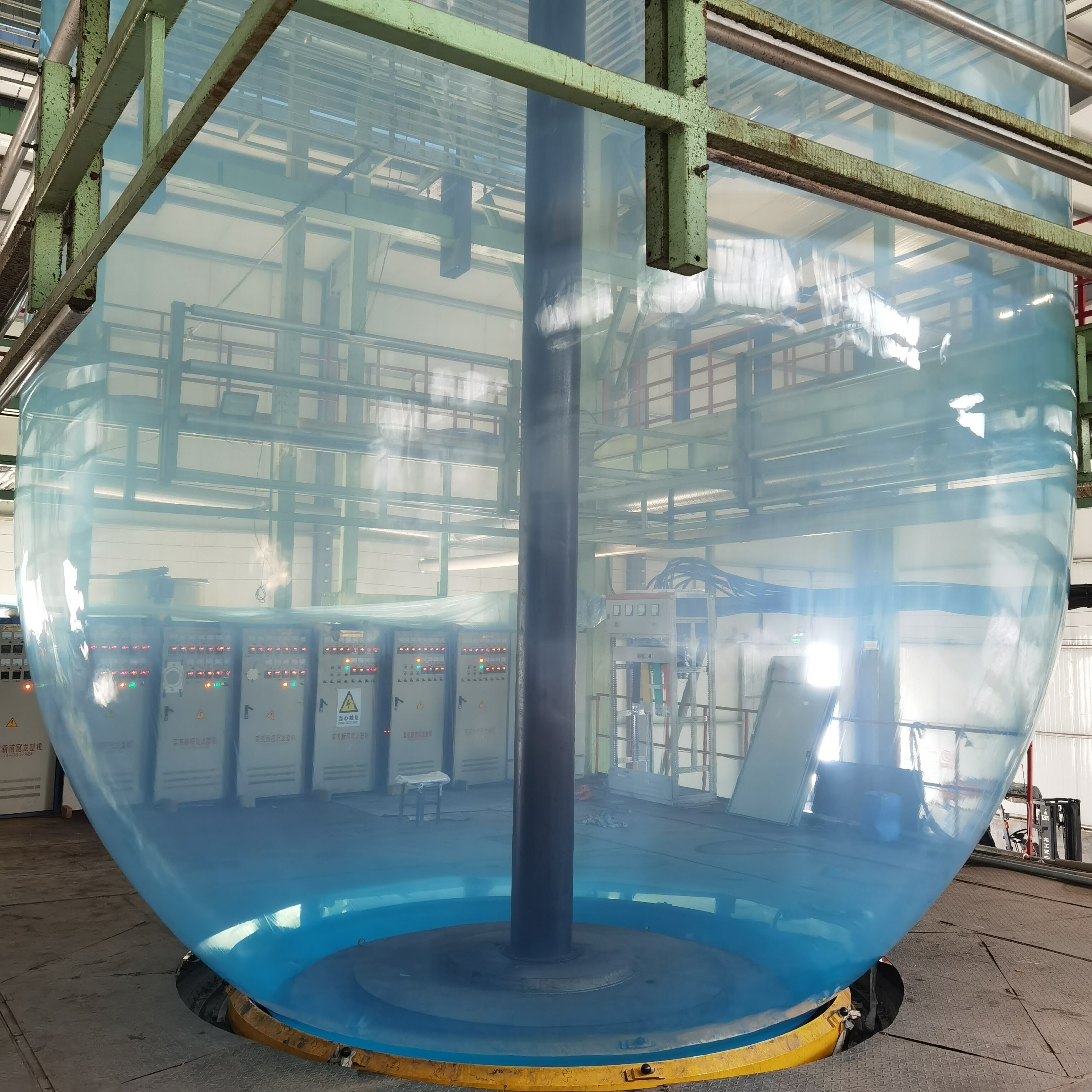

High quality PO (polyolefin) film represents a versatile and advanced packaging solution that combines superior strength with remarkable flexibility. This innovative material features a unique molecular structure that provides exceptional clarity, dimensional stability, and outstanding barrier properties against moisture and external contaminants. The film undergoes a sophisticated manufacturing process that ensures uniform thickness distribution and enhanced surface properties, making it ideal for various industrial and commercial applications. With its excellent heat-sealing capabilities and consistent performance across different temperature ranges, high quality PO film delivers reliable protection for packaged goods while maintaining their integrity and freshness. The film's advanced formulation includes UV stabilizers and antioxidants, extending its durability and preventing degradation under various environmental conditions. Notable for its excellent printability and compatibility with different printing technologies, this film enables vibrant, long-lasting branding solutions. Furthermore, its superior mechanical properties, including high tensile strength and puncture resistance, make it particularly suitable for demanding packaging applications in food, pharmaceutical, and consumer goods industries.